Lakewood Instruments

NexSys System From Lakewood Instruments

|

All features, parameters, settings, and functional requirements to operate, program, and monitor the NexSys control system are accessible from the touch screen and DO NOT require the use of an external input, PC or device to operate or access. The NexSys control system even includes On-Board Help Screens with wiring, programming, and maintenance instructions. The NexSys control system comes standard with the following system interfaces and DMX outputs: LON EIA 709 FTT10, BACnet IP, and MODbus TCP. The unit comes from the factory ready to integrate readings into a BAS, including: The state of any installed relay (On/Off) , Water meter readings, Conductivity readings, Additional sensor readings (ph, ORP), sensor alarms, Additional 4-20mA input readings, Flow condition, and other digital inputs. The NexSys control system comes standard with Ethernet capability through a browser (HTML5) interface that allows 100% access to all features and control parameters of the controller.

Features:

Relay Outputs (Internal): Six relays rated at 120VAC. Relay ratings, 3 AMP per relay, 15 amps total Chemical feed and additional relay programming methods, available selections

Inputs: Up to 8 active Sensor inputs (2 TWR Conductivity, 2 pH and 2 ORP, 2 MU Conductivity) can be ordered in various combinations. Water meters - Two Water meter inputs are standard and be factory or field upgradeable for two additional (Total four) water meter inputs Each relay shall be capable of being configured to operate with either� of the two flow (digital) input for activation or deactivation Expansion capabilities: The unit will be factory or field upgraded. Additional expansion features include:

Interface/Communications: The NexSys comes standard with the following system interfaces: LON EIA 709 FTT10, BACnet IP and MODbus TCP (As well as Incorporate DMX outputs). The unit shall comes from the factory with all tables and outputs defined for� Information being transmitted, including:

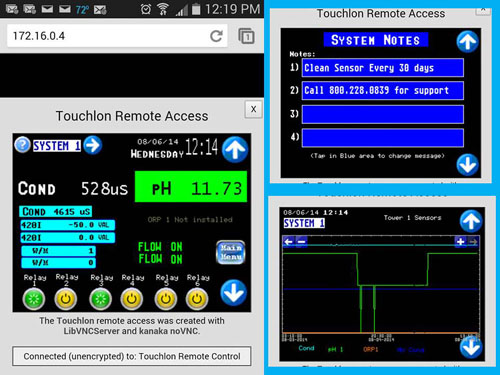

Remote Communications: The NexSys controller has standard Ethernet capability through and HTML interface that allows 100% access to all features and control parameters of the controller. The NexSys remote access allows the user to alter, confirm and manipulate 100% of configurations. All features, parameters, settings and functional requirements to operate, program and monitor the NexSys controller are accessible from the touch screen and DO NOT require the use of an external input, PC or device to operate or access. (BMS config requires use of interface program) The NexSys will be upgradeable to send E-service reports to a subscribed service (user to set up account with a service at their discretion). The NexSys displays operating values, via a color touch screen, color coded graphs for all sensor and relay operation times and readings with time and date stamps. User shall be able to manipulate graph via zoom and scroll features. Approvals Is in qualification testing for UL and CSA Listed (ETL listing is acceptable) NEMA 4X enclosure Power: Transformer power ratings of 120/240 VAC 50/60 Hz. Release date: 30 March 2014 Screen Shots  Operator Screens for setup and System notes (user fields changeable) Screens shown above: Upper left: The main screen where you can manually operate relays and verify system readings Upper Right: The built in calculation screen for figuring Pre Bleed for Bio feeds. (User inputs) Lower Left: Current alarm conditions. The user can choose to be notified by email and also have the alarms logged. Lower Right: A system notes screen where the user can leave instructions for the next person.

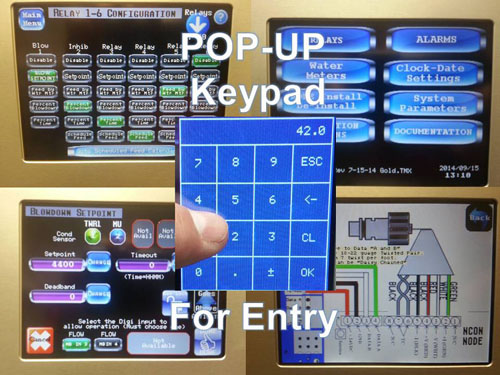

Screens shown above: Upper Left: Relay configuration screen allows operator to choose how and when relays operate and interact. Upper Right: System choice screen for configuration and documentation. Lower Left: Configuring a setpoint Blowdown relay. All on one screen. Tap and enter. No need to go between or use up down arrows to try and enter a number Lower Right: Internal Manual Documentation to show how to wire and care for probes and boards.

Screens shown above: Screens can be viewed from HTML5 capable browsers (Chrome, Firefox,etc) and Smartphones using remote access. The screen you see is the exact same screen you see at the controller. No more mucking about to find a function on a web page that is not laid out in the same menu system as the actual controller interface. (Including live graphing of features IN COLOR. |

The NexSys control system is the latest in a long line of reliable, easy to use controllers from Lakewood Instruments. The NexSys control system uses the latest in microprocessor technology with a 5.7” Color Touch Screen interface for a high level of application flexibility.

The NexSys control system is the latest in a long line of reliable, easy to use controllers from Lakewood Instruments. The NexSys control system uses the latest in microprocessor technology with a 5.7” Color Touch Screen interface for a high level of application flexibility.